TITLE 326 AIR POLLUTION CONTROL BOARD

Final Rule

LSA Document #09-222(F)

DIGEST

Adds 326 IAC 8-18, 326 IAC 8-19, 326 IAC 8-20, and 326 IAC 8-21, synthetic organic chemical manufacturing industry (SOCMI) air oxidation, distillation, and reactor processes, batch process vents, industrial wastewater treatment, and aerospace manufacturing and rework operations, respectively, concerning new volatile organic compound (VOC) reasonably available control technology (RACT) rules for Lake County and Porter County. Effective 30 days after filing with the Publisher.

Date of First Hearing: July 1, 2009.

Date of Second Hearing: September 2, 2009.

Rule 18. Synthetic Organic Chemical Manufacturing Industry Air Oxidation, Distillation, and Reactor Processes

Authority: IC 13-14-8; IC 13-17-3-4; IC 13-17-3-11

Sec. 1. (a) This rule applies to any vent stream originating from a process unit in which an air oxidation and distillation operation or reactor process is located that meets the following criteria:

(1) Is located in Lake County or Porter County.

(2) Produces one (1) or more of the chemicals as a product, coproduct, byproduct, or intermediate listed in:

(A) Appendix A of Control of Volatile Organic Compound Emissions from Reactor Processes and Distillation Operations in Synthetic Organic Chemical Manufacturing Industry (SOCMI) for reactor and distillation CTG (EPA-450/4-91-031, August 1993)*; or

(B) 40 CFR 60.617* for air oxidation unit processes.

(b) Air oxidation unit processes, distillation operations, and reactor processes are defined in 40 CFR 60.611* "air oxidation unit processes", 40 CFR 60.661* "distillation operation", and 40 CFR 60.701* "reactor processes".

(c) Product means any compound or chemical listed in Appendix A of Control of Volatile Organic Compound Emissions from Reactor Processes and Distillation Operations in Synthetic Organic Chemical Manufacturing Industry (SOCMI) for reactor and distillation CTG (EPA-450/4-91-031, August 1993)* that is produced as that chemical for sale as a product, byproduct, coproduct, or intermediate or for use in the production of other chemicals or compounds.

(d) For purposes of this rule, reference to total organic compounds or TOC in 40 CFR 60, Subpart III*, 40 CFR 60, Subpart NNN* or 40 CFR 60, Subpart RRR* shall be considered to mean VOC as defined in 326 IAC 1-2-90.

(e) For process vents that are subject to equivalent VOC control provisions under an existing 40 CFR Part 60 or 40 CFR Part 63 standard, compliance with the requirements of the existing 40 CFR Part 60 or 40 CFR Part 63 standard shall constitute compliance with the provisions of this rule.

*These documents are incorporated by reference. Copies may be obtained from the Government Printing Office, 732 North Capitol Street NW, Washington, D.C. 20401 or are available for review and copying at the Indiana Department of Environmental Management, Office of Legal Counsel, Indiana Government Center North, Thirteenth Floor, 100 North Senate Avenue, Indianapolis, Indiana 46204.

(Air Pollution Control Board; 326 IAC 8-18-1; filed Nov 3, 2009, 3:32 p.m.: 20091202-IR-326090222FRA)

326 IAC 8-18-2 Air oxidation unit processes

Authority: IC 13-14-8; IC 13-17-3-4; IC 13-17-3-11

Sec. 2. (a) The owner or operator of a source with air oxidation unit processes meeting the applicability criteria in section 1 of this rule shall comply with the requirements of 40 CFR 60, Subpart III*.

(b) The exemption listed in 40 CFR 60.610(c)* shall apply to an owner or operator otherwise subject to this rule.

(c) Notwithstanding 40 CFR 60.610*, for purposes of this rule:

(1) an affected source shall be one that is described by the criteria in 40 CFR 60.610(a)* without consideration of the specific date of construction, modification, or reconstruction of the source; and

(2) the owner or operator of an affected source shall comply with this rule no later than April 1, 2011.

(d) Notwithstanding 40 CFR 60.615(a)*, each owner or operator subject to this rule shall notify the department how the source will comply with the specific provisions of 40 CFR 60.612*:

(1) no later than one (1) year after the effective date of this rule; or

(2) no later than sixty (60) days after becoming subject to this section;

whichever is later.

(e) For the purposes of this rule, 40 CFR 60.616* is not applicable.

*These documents are incorporated by reference. Copies may be obtained from the Government Printing Office, 732 North Capitol Street NW, Washington, D.C. 20401 or are available for review and copying at the Indiana Department of Environmental Management, Office of Legal Counsel, Indiana Government Center North, Thirteenth Floor, 100 North Senate Avenue, Indianapolis, Indiana 46204.

(Air Pollution Control Board; 326 IAC 8-18-2; filed Nov 3, 2009, 3:32 p.m.: 20091202-IR-326090222FRA)

Authority: IC 13-14-8; IC 13-17-3-4; IC 13-17-3-11

Sec. 3. (a) The owner or operator of a source with distillation operations meeting the applicability criteria in section 1 of this rule shall comply with the requirements of 40 CFR 60, Subpart NNN*.

(b) The following exemptions apply:

(1) Exemptions listed in 40 CFR 60.660(c)* shall apply to an owner or operator otherwise subject to this rule.

(2) Any vent stream for a distillation operation with a total VOC concentration of less than five hundred (500) parts per million by volume is not subject to this rule except for the test method and procedure and the record keeping and reporting requirements specified in 40 CFR 60.660(c)(6)*.

(c) Notwithstanding 40 CFR 60.660*, for purposes of this rule:

(1) an affected source shall be one that is described by the criteria in 40 CFR 60.660(a)* without consideration of the specific date of construction, modification, or reconstruction of the source;

(2) an applicable chemical is one described in section 1(a)(2)(A) of this rule instead of 40 CFR 60.667*; and

(3) the owner or operator of an affected source shall comply with this rule no later than April 1, 2011.

(d) Notwithstanding 40 CFR 60.665(a)*, each owner or operator subject to this rule shall notify the department how the source will comply with the specific provisions of 40 CFR 60.662*:

(1) no later than one (1) year after the effective date of this rule; or

(2) no later than sixty (60) days after becoming subject to this section;

whichever is later.

(e) For the purposes of this rule, 40 CFR 60.666* is not applicable.

*These documents are incorporated by reference. Copies may be obtained from the Government Printing Office, 732 North Capitol Street NW, Washington, D.C. 20401 or are available for review and copying at the Indiana Department of Environmental Management, Office of Legal Counsel, Indiana Government Center North, Thirteenth Floor, 100 North Senate Avenue, Indianapolis, Indiana 46204.

(Air Pollution Control Board; 326 IAC 8-18-3; filed Nov 3, 2009, 3:32 p.m.: 20091202-IR-326090222FRA)

Authority: IC 13-14-8; IC 13-17-3-4; IC 13-17-3-11

Sec. 4. (a) The owner or operator of a source with reactor processes meeting the applicability criteria in section 1 of this rule shall comply with the requirements of 40 CFR 60, Subpart RRR*.

(b) The following exemptions apply:

(1) Exemptions listed in 40 CFR 60.700(c)* shall apply to an owner or operator otherwise subject to this rule, except that the cutoff for the vent stream flow rate is eighty-five ten-thousandths (0.0085) standard cubic meter per minute (scm/min), not eleven-thousandths (0.011) scm/min as specified in 40 CFR 60.700(c)(4)*.

(2) Any vent stream for a reactor operation with a total VOC concentration of less than five hundred (500) parts per million by volume is not subject to this rule except for the test method and procedure and the record keeping and reporting requirements specified in 40 CFR 60.700(c)(8)*.

(c) Notwithstanding 40 CFR 60.700*, for purposes of this rule:

(1) an affected source shall be one that is described by the criteria in 40 CFR 60.700(a)* without consideration of the specific date of construction, modification, or reconstruction of the source;

(2) an applicable chemical is one described in section 1(a)(2)(A) of this rule instead of 40 CFR 60.707*; and

(3) the owner or operator of an affected source shall comply with this rule no later than April 1, 2011.

(d) Notwithstanding 40 CFR 60.705(a)*, each owner or operator subject to this rule shall notify the department how the source will comply with the specific provisions of 40 CFR 60.702*:

(1) no later than one (1) year after the effective date of this rule; or

(2) no later than sixty (60) days after becoming subject to this section;

whichever is later.

(e) For the purposes of this rule, 40 CFR 60.706* is not applicable.

*These documents are incorporated by reference. Copies may be obtained from the Government Printing Office, 732 North Capitol Street NW, Washington, D.C. 20401 or are available for review and copying at the Indiana Department of Environmental Management, Office of Legal Counsel, Indiana Government Center North, Thirteenth Floor, 100 North Senate Avenue, Indianapolis, Indiana 46204.

(Air Pollution Control Board; 326 IAC 8-18-4; filed Nov 3, 2009, 3:32 p.m.: 20091202-IR-326090222FRA)

Authority: IC 13-14-8; IC 13-17-3-4; IC 13-17-3-11

Sec. 5. If the owner or operator of a source employs a VOC emission combustion control device that does not achieve compliance with an emission limitation in 40 CFR 60.612*, 40 CFR 60.662*, or 40 CFR 60.702* as applicable under this rule, the owner or operator is not required to comply with the emission limitation until the combustion control device is replaced for reasons other than compliance with this rule. A combustion control device is considered to be replaced when one (1) of the following occur:

(1) All of the control device is replaced.

(2) The cost of repair of the control device or the cost of replacement of part of the control device exceeds fifty percent (50%) of the cost of replacing the entire control device with a control device that is capable of complying with the respective requirements of 40 CFR 60.612*, 40 CFR 60.662*, or 40 CFR 60.702*.

*These documents are incorporated by reference. Copies may be obtained from the Government Printing Office, 732 North Capitol Street NW, Washington, D.C. 20401 or are available for review and copying at the Indiana Department of Environmental Management, Office of Legal Counsel, Indiana Government Center North, Thirteenth Floor, 100 North Senate Avenue, Indianapolis, Indiana 46204.

(Air Pollution Control Board; 326 IAC 8-18-5; filed Nov 3, 2009, 3:32 p.m.: 20091202-IR-326090222FRA)

Rule 19. Control of Volatile Organic Compound Emissions from Process Vents in Batch Operations

Authority: IC 13-14-8; IC 13-17-3-4; IC 13-17-3-11

Sec. 1. (a) This rule applies to any source that has a batch process train associated with any of the SIC codes 2821, 2833, 2834, 2861, 2865, 2869, or 2879, and that meets the following criteria:

(1) Is located in Lake County or Porter County.

(2) Has the potential to emit emissions of VOCs greater than or equal to one hundred (100) tons per year from all of the following:

(A) Process vents from all batch operations.

(B) All noncontrol technique guideline (non-CTG) emission units.

(C) Unregulated emissions from CTG emission units, except emission units regulated under 40 CFR 60, Subpart BBB*; 40 CFR 60, Subpart III*; 40 CFR 60, Subpart NNN*; or 40 CFR 63, Subpart T*.

(b) If a source meets the applicability requirements under subsection (a), but reduces its potential to emit for VOCs by means of federally enforceable operational restriction (for example, production, hours of operation, or capacity utilization) to less than one hundred (100) tons per year by April 1, 2011, the source is not subject to the requirements of section 3 of this rule.

(c) The owner or operator of a batch process train at a source that meets the applicability criteria of subsection (a) is subject to this rule with the following exceptions:

(1) Any source subject to control requirements in 326 IAC 8-5-3 is not subject to this rule.

(2) The following unit operations within a batch process train and batch process trains are exempt from section 3 of this rule, control requirements, but are subject to section 7 of this rule, record keeping, and section 8 of this rule, reporting:

(A) Any unit operation with uncontrolled total annual mass emissions of less than or equal to five hundred (500) pounds per year of VOC. Such unit operations are also excluded from the calculation of the total annual mass emissions for a batch process train. If the uncontrolled total annual mass emissions from such exempt unit operation exceed five hundred (500) pounds per year of VOC in any subsequent year, the owner or operator shall calculate and determine applicability in accordance with subsection (d) for both the individual unit operation and the batch process train containing the unit operation.

(B) Any batch process train containing process vents that have, in the aggregate, uncontrolled total annual mass emissions, as determined in accordance with section 4(a)(1) of this rule, of less than thirty thousand (30,000) pounds per year of VOC for all products manufactured in such batch process train.

(d) The applicability equations in subsection (e), which require the calculation of uncontrolled total annual mass emissions and flow rate value, shall be used to determine whether a unit operation or a batch process train is subject to the control requirements in section 3 of this rule. The applicability equations shall be applied to the following:

(1) Any unit operation with uncontrolled total annual mass emissions that exceed five hundred (500) pounds per year and with a VOC concentration greater than five hundred (500) parts per million by volume (ppmv). In this individual determination, no applicability analysis shall be performed for any unit operation with a VOC concentration of less than or equal to five hundred (500) ppmv.

(2) Any batch process train containing process vents that, in the aggregate, have uncontrolled total annual mass emissions of thirty thousand (30,000) pounds per year or more of VOC from all products manufactured in the batch process train. Any unit operation with uncontrolled total annual mass emissions exceeding five hundred (500) pounds per year, regardless of VOC concentration, shall be included in the aggregate applicability analysis.

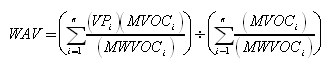

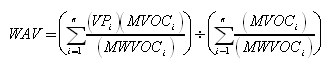

(e) Applicability equations under this subsection are specific to volatility and are as follows:

(1) Abbreviations are as follows:

(A) FR = calculated applicability flow rate, scfm.

(B) UTAME = uncontrolled total annual mass emissions of VOC, expressed as pounds per year.

(C) WAV = weighted average volatility.

(D) MVOCi = mass of VOC component i.

(E) MWVOCi = molecular weight of VOC component i.

(F) VPi = vapor pressure of VOC component i.

(G) i = subscript denoting a specific VOC component.

(H) n = total number of VOC components.

(2) Weighted average volatility shall be calculated as follows:

(3) For purposes of determining applicability, calculated applicability flow rate values shall be determined as follows:

(A) Process vents with a WAV that is less than or equal to seventy-five (75) mmHg at twenty (20) degrees Celsius (sixty-eight (68) degrees Fahrenheit), shall use the following equation:

FR = [0.07 (UTAME)] - 1,821

(B) Process vents with a WAV that is greater than seventy-five (75) mmHg, but less than or equal to one hundred fifty (150) mmHg at twenty (20) degrees Celsius (sixty-eight (68) degrees Fahrenheit), shall use the following equation:

FR = [0.031 (UTAME)] - 494

(C) Process vents with a WAV that is greater than one hundred fifty (150) mmHg at twenty (20) degrees Celsius (sixty-eight (68) degrees Fahrenheit), shall use the following equation:

FR = [0.013 (UTAME)] – 301

(f) For purposes of subsection (a), an emission unit shall be considered regulated by a rule, section, or subpart if it is subject to the limits of that rule, section, or subpart. An emission unit is not considered regulated by a rule, section, or subpart if it is not subject to the limits of that rule, section, or subpart. For example, if the emission unit is covered by an exemption in the rule, section, or subpart, or the applicability criteria of the rule, section, or subpart are not met, then the source is not subject to rule, section, or subpart. An emission unit is also not considered regulated if there is no rule contained in this article regulating the source category.

(Air Pollution Control Board; 326 IAC 8-19-1; filed Nov 3, 2009, 3:32 p.m.: 20091202-IR-326090222FRA)

Authority: IC 13-14-8; IC 13-17-3-4; IC 13-17-3-11

Sec. 2. The following definitions apply throughout this rule:

(1) "Aggregate" means the summation of all process vents containing VOC within a process.

(2) "Batch cycle" means a manufacturing event of an intermediate or product from start to finish in a batch process train.

(3) "Batch operation" means a noncontinuous operation in which a discrete quantity or batch of feed is charged into a unit operation within a batch process train and processed at one (1) time. Batch operation includes noncontinuous operations in which the equipment is fed intermittently or discontinuously. Addition of raw material and withdrawal of product do not occur simultaneously in a batch operation. After each batch operation, the equipment is generally emptied before a fresh batch is started.

(4) "Batch process train" means the collection of equipment, such as:

(A) reactors;

(B) filters;

(C) dryers;

(D) distillation columns;

(E) extractors;

(F) crystallizers;

(G) blend tanks;

(H) neutralizer tanks;

(I) digesters;

(J) surge tanks; and

(K) product separators;

configured to produce a specific product or intermediate by a batch operation. A batch process train terminates at the point of storage or product handling of the product or intermediate being produced in the batch process train. Irrespective of the product being produced, a batch process train that is independent of other processes shall be considered a single batch process train for purposes of this rule.

(5) "Boiler" means any enclosed combustion device that extracts useful energy in the form of steam.

(6) "Btu" means British thermal unit.

(7) "Continuous recorder" means a data recording device that either records:

(A) an instantaneous data value at least once every fifteen (15) minutes; or

(B) fifteen (15) minute or more frequent block average values.

(8) "Control device" means any device or combination of devices designed to recover or destroy VOC vapors received from the process vents. A recovery device that is a required part of the process, for example, but not limited to, condensers operating under reflux conditions, is not a control device.

(9) "Emission event" means a discrete period of venting that is associated with a unit operation. For example, a displacement of vapor resulting from the charging of a unit operation with VOC will result in a discrete emission event that will last through the duration of the charge and will have an average flow rate equal to the rate of the charge. The expulsion of expanded unit operation vapor space when the vessel is heated is also an emission event. Both of these examples of emission events and others may occur in the same unit operation during the course of the batch cycle. If the flow rate measurement for any discrete period of venting is zero (0), then the event is not an emission event for purposes of this rule.

(10) "Flame zone" means the portion of the combustion chamber in a boiler occupied by the flame envelope.

(11) "Incinerator" means any enclosed combustion device that is used for destroying organic compounds. Auxiliary fuel may be used to heat waste gas to combustion temperatures. Any energy recovery section present is not physically formed into one (1) section; rather, the energy recovery system is a separate section following the combustion section and the two are joined by ducting or connections that carry fuel gas.

(12) "MmHg" means millimeters of mercury.

(13) "Permit" means a permit issued by the commissioner under 326 IAC 2.

(14) "Ppmv" means parts per million by volume.

(15) "Process vent" means a vent gas stream that is discharged from a unit operation or multiple unit operations within the same batch process train that are manifolded together into a common header. A process vent begins at the inlet to the control device prior to mixing with vent gas streams from other process trains or unrelated operations or, in the absence of a control device, at the point of discharge to the atmosphere. The term does not include exhaust streams from exhaust hood and building ventilation fans that are used to provide ventilation for workers and not to collect and discharge emissions from specific unit operations. Process vents exclude the following:

(A) Relief valve discharges.

(B) Leaks from equipment.

(C) Vents from storage tanks.

(D) Vents from transfer or loading operations.

(E) Vents from wastewater.

(16) "Recovery device" means an individual unit of equipment, such as:

(A) an absorber;

(B) a carbon adsorber; or

(C) a condenser;

capable of and used for the purpose of recovering chemicals for use, reuse, or sale.

(17) "Recovery system" means an individual recovery device or series of such devices applied to the same vent stream.

(18) "Scfm" means standard cubic feet per minute.

(19) "Standard industrial classification code" or "SIC code" means a series of four (4) digit codes devised by the office of management and budget (OMB) of the federal government to classify establishments according to the type of economic activity in which they are engaged.

(20) "Unit operation" means one (1) or more pieces of process equipment used to make a single change to the physical or chemical characteristics of one (1) or more process streams. Equipment used for these purposes includes, but is not limited to, the following:

(A) Reactors.

(B) Filters.

(C) Dryers.

(D) Distillation columns.

(E) Extractors.

(F) Crystallizers.

(G) Blend tanks.

(H) Neutralizer tanks.

(I) Digesters.

(J) Surge tanks.

(K) Product separators.

(Air Pollution Control Board; 326 IAC 8-19-2; filed Nov 3, 2009, 3:32 p.m.: 20091202-IR-326090222FRA)

326 IAC 8-19-3 Control requirements for VOC emissions from process vents

Authority: IC 13-14-8; IC 13-17-3-4; IC 13-17-3-11

Sec. 3. The control requirements set forth in this rule shall apply to process vents of batch process trains and unit operations within batch process trains (batch operations) as follows:

(1) The owner or operator of a unit operation with an average flow rate, as determined in accordance with section 4(b) of this rule, below the flow rate value calculated by the applicability equations contained in section 1(e) of this rule, shall reduce uncontrolled VOC emissions from such unit operation by an overall efficiency, on average, of at least ninety percent (90%), or to twenty (20) ppmv, per batch cycle.

(2) The owner or operator of a batch process train with an average flow rate, as determined in accordance with section 4(b)(2) of this rule, below the flow rate value calculated by the applicability equations contained in section 1(e) of this rule, shall reduce uncontrolled VOC emissions from such batch process train by an overall efficiency, on average, of at least ninety percent (90%), or to twenty (20) ppmv, per batch cycle.

(3) If a boiler or process heater is used to comply with subdivision (1) or (2), the vent stream shall be introduced into the flame zone of the boiler or process heater.

(4) If a flare is used to comply with subdivision (1) or (2), the flare shall comply with the requirements of 40 CFR 60.18*.

(5) If a process, not subject to this rule, vents an emergency relief discharge into a common flare header of this flare, the requirements of 40 CFR 60.18* shall not apply during the emergency relief discharge.

*These documents are incorporated by reference. Copies may be obtained from the Government Printing Office, 732 North Capitol Street NW, Washington D.C. or are available for review and copying at the Indiana Department of Environmental Management, Office of Legal Counsel, Indiana Government Center North, Thirteenth Floor, 100 North Senate Avenue, Indianapolis, Indiana 46204.

(Air Pollution Control Board; 326 IAC 8-19-3; filed Nov 3, 2009, 3:32 p.m.: 20091202-IR-326090222FRA)

326 IAC 8-19-4 Determination of uncontrolled total annual mass emissions and actual weighted average flow rate values for a batch process train or unit operation

Authority: IC 13-14-8; IC 13-17-3-4; IC 13-17-3-11

Sec. 4. (a) Uncontrolled total annual mass emissions shall be determined by the following methods:

(1) Direct process vent emissions measurements taken prior to any release to the atmosphere, following any recovery device, prior to mixing with vents from other process trains or unrelated operations, and prior to any control device, provided the measurements conform with the requirements of measuring the mass flow rate of VOC incoming to the control device as set forth in section 5(f)(2), 5(f)(3)(A)(i), and 5(f)(3)(A)(ii) of this rule.

(2) Engineering estimates of the uncontrolled VOC emissions from a process vent or process vents, in the aggregate, within a batch process train, using either the potential or permitted number of batch cycles per year or total production as represented in the permit for the batch process train as follows:

(A) Engineering estimates of the uncontrolled VOC emissions shall be based upon accepted chemical engineering principles, measurable process parameters, or physical or chemical laws and their properties. Examples of methods include, but are not limited to, the following:

(i) Use of material balances based on process stoichiometry to estimate maximum VOC concentrations.

(ii) Estimation of maximum flow rate based on physical equipment design, such as pump or blower capacities.

(iii) Estimation of VOC concentrations based on saturation conditions.

(B) All data, assumptions, and procedures used in any engineering estimate shall be documented.

(b) Average flow rate shall be determined by any of the following methods:

(1) Direct process vent flow rate measurements taken prior to any release to the atmosphere, following any recovery device, prior to mixing with vents from other process trains or unrelated operations, and prior to any control device, provided the measurements conform with the requirements of measuring incoming volumetric flow rate set forth in section 5(f)(2) of this rule.

(2) Average flow rate for a unit operation having multiple emission events or batch process trains shall be the weighted average flow rate, calculated as follows:

| | | |

| Where: | WAF | = | actual weighted average flow rate for a unit operation or batch process train. |

| | AFRi | = | average flow rate of emission event i. |

| | ADEi | = | annual duration of emission event i. |

| | i | = | subscript denoting a specific emission event. |

| | n | = | number of emission events. |

(3) Engineering estimates calculated in accordance with the requirements in subsection (a)(2).

(c) For purposes of determining the average flow rate for steam vacuuming systems, the steam flow shall be included in the average flow rate calculation.

(Air Pollution Control Board; 326 IAC 8-19-4; filed Nov 3, 2009, 3:32 p.m.: 20091202-IR-326090222FRA)

326 IAC 8-19-5 Compliance testing requirements

Authority: IC 13-14-8; IC 13-17-3-4; IC 13-17-3-11

Sec. 5. (a) Upon the commissioner's request, the owner or operator of a batch process train or unit operation within a batch process train shall conduct testing to demonstrate compliance with section 3 this rule. The owner or operator shall, at its own expense, conduct the tests in accordance with the applicable test methods and procedures specified in subsections (d), (e), and (f).

(b) Notwithstanding subsection (a), flares and process boilers used to comply with the control requirements of section 3 of this rule shall be exempt from compliance testing requirements.

(c) When a flare is used to comply with the control requirements of section 3 of this rule, the flare shall comply with the requirements of 40 CFR 60.18*.

(d) The owner or operator of a batch process train or unit operation within a batch process train that is exempt from the control requirements of section 3 of this rule due to:

(1) an average flow rate that is equal to or above the calculated applicability flow rate; or

(2) a VOC concentration of less than or equal to five hundred (500) ppmv (unit operation);

shall demonstrate, upon the commissioner's request, the absence of oversized gas moving equipment in any manifold. Gas moving equipment shall be considered oversized if it exceeds the maximum requirements of the exhaust flow rate by more than thirty percent (30%).

(e) For the purpose of demonstrating compliance with the control requirements in section 3 of this rule, the batch process train or unit operation shall be run at representative operating conditions and flow rates during any compliance test.

(f) The following methods in 40 CFR 60, Appendix A* shall be used to demonstrate compliance with the reduction efficiency requirement set forth in section 3 of this rule:

(1) U.S. EPA Method 1 or 1A, as appropriate, for selection of the sampling sites if the flow measuring device is not a rotameter. The control device inlet sampling site for determination of vent stream VOC composition reduction efficiency shall be prior to the control device and after the control device.

(2) U.S. EPA Method 2, 2A, 2B, 2C, or 2D, as appropriate, for determination of gas stream volumetric flow rate flow measurements, which shall be taken continuously. No traverse is necessary when the flow measuring device is an ultrasonic probe.

(3) U.S. EPA Method 25A or U.S. EPA Method 18, if applicable, to determine the concentration of VOC in the control device inlet and outlet as follows:

(A) The sampling time for each run shall be as follows:

(i) For batch cycles less than eight (8) hours in length, readings shall be taken continuously over the entire length of the batch cycle with a maximum of fifteen (15) minute intervals between measurements if using U.S. EPA Method 25A. If using U.S. EPA Method 18, readings shall be taken continuously with a maximum of fifteen (15) minute intervals between measurements throughout the batch cycle unless it becomes necessary to change the impinger train, in which case a thirty (30) minute interval shall not be exceeded.

(ii) For batch cycles of eight (8) hours and greater in length, the owner or operator may either test in accordance with the test procedures defined in item (i) or the owner or operator may elect to perform tests, pursuant to either U.S. EPA Method 25A or U.S. EPA Method 18, only during those portions of each emission event that define the emission profile of each emission event occurring within the batch cycle. For each emission event of less than four (4) hours in duration, the owner or operator shall test continuously over the entire emission event as set forth in item (i). For each emission event of greater than four (4) hours in duration, the owner or operator shall elect either to perform a minimum of three (3) one (1) hour test runs during the emission event or shall test continuously over the entire emission event within each unit operation in the batch process train. To demonstrate that the portion of the emission event to be tested defines the emission profile for the emission event, the owner or operator electing to rely on this option shall develop an emission profile for the entire emission event. The emission profile shall be based upon either process knowledge or test data collected. Examples of information that could constitute process knowledge include, but are not limited to, calculations based on material balances and process stoichiometry. Previous test results may be used provided the results are still relevant to the current

process vent stream conditions.

(B) The mass emission rate from the process vent or inlet to the control device shall be determined by combining concentration and flow rate measurements taken simultaneously at sampling sites selected in accordance with subdivision (1) throughout the batch cycle.

(C) The mass emission rate from the control device outlet shall be obtained by combining concentration and flow rate measurements taken simultaneously at sampling sites selected in accordance with subdivision (1) throughout the batch cycle.

(D) The efficiency of the control device shall be determined by integrating the mass emission rates obtained in clauses (B) and (C) over the time of the batch cycle and dividing the difference in inlet and outlet mass flow totals by the inlet mass flow total.

(g) The owner or operator of a batch process train or unit operation may propose an alternative test method or procedures to demonstrate compliance with the control requirements set forth in section 3 of this rule. The method or procedures shall be:

(1) approved by the commissioner and U.S. EPA in writing; and

(2) included as federally enforceable permit conditions.

(h) In the absence of a request by the commissioner to conduct compliance testing in accordance with provisions of this rule, the owner or operator may demonstrate compliance by the use of engineering estimates or process stoichiometry.

(i) During the compliance test conducted to demonstrate compliance with the control requirements of section 3 of this rule, the owner or operator shall establish the operating limits (operating parameter values) for the monitoring devices required under section 6 of this rule.

*These documents are incorporated by reference. Copies may be obtained from the Government Printing Office, 732 North Capitol Street NW, Washington, D.C. or are available for review and copying at the Indiana Department of Environmental Management, Office of Legal Counsel, Indiana Government Center North, Thirteenth Floor, 100 North Senate Avenue, Indianapolis, Indiana 46204.

(Air Pollution Control Board; 326 IAC 8-19-5; filed Nov 3, 2009, 3:32 p.m.: 20091202-IR-326090222FRA)

Authority: IC 13-14-8; IC 13-17-3-4; IC 13-17-3-11

Sec. 6. (a) Every owner or operator using an incinerator to comply with section 3 of this rule shall install, calibrate, maintain, and operate, according to manufacturer's specifications, temperature monitoring devices with an accuracy of plus or minus one percent (1%) of the temperature being measured expressed in degrees Celsius or plus or minus one and eight-tenths percent (1.8%) of the temperature being measured expressed in degrees Fahrenheit, each equipped with a continuous recorder as follows:

(1) Where a catalytic incinerator is used, temperature monitoring devices shall be installed in the gas stream immediately before and after the catalyst bed.

(2) Where an incinerator other than a catalytic incinerator is used, a temperature monitoring device shall be installed in the combustion chamber.

(b) The owner or operator using a flare to comply with section 3 of this rule shall install, calibrate, maintain, and operate, according to manufacturer's specifications, a heat sensing device, such as an ultraviolet beam sensor or thermocouple, at the pilot light to indicate continuous presence of a flame.

(c) Every owner or operator using a scrubber to comply with section 3 of this rule shall install, calibrate, maintain, and operate, according to manufacturer's specifications:

(1) a temperature monitoring device for scrubbant liquid having an accuracy of plus or minus one percent (1%) of the temperature being monitored expressed in degrees Celsius or plus or minus one and eight-tenths percent (1.8%) of the temperature being measured expressed in degrees Fahrenheit and a specific gravity device for scrubbant liquid, each equipped with a continuous recorder; or

(2) a VOC monitoring device used to indicate the concentration of VOC exiting the control device based on a detection principle, such as infrared, photoionization, or thermal conductivity, equipped with a continuous recorder.

(d) Every owner or operator using a condenser to comply with section 3 of this rule shall install, calibrate, maintain, and operate, according to manufacturer's specifications:

(1) a condenser exit temperature monitoring device equipped with a continuous recorder and having an accuracy of plus or minus one percent (1%) of the temperature being monitored expressed in degrees Celsius or plus or minus one and eight-tenths percent (1.8%) of the temperature being measured expressed in degrees Fahrenheit, equipped with a continuous recorder; or

(2) a VOC monitoring device used to indicate the concentration of VOC, such as infrared, photoionization, or thermal conductivity, each equipped with a continuous recorder.

(e) Every owner or operator using a carbon adsorber to comply with section 3 of this rule shall install, calibrate, maintain, and operate, according to the manufacturer's specifications:

(1) an integrating regeneration steam flow monitoring device having an accuracy of plus or minus ten percent (10%), and a carbon bed temperature monitoring device having an accuracy of plus or minus one percent (1%) of the temperature being monitored expressed in degrees Celsius or plus or minus one and eight-tenths percent (1.8%) of the temperature being measured expressed in degrees Fahrenheit, both equipped with a continuous recorder; or

(2) a VOC monitoring device used to indicate the concentration level of VOC exiting the device based on a detection principle, such as infrared, photoionization, or thermal conductivity, equipped with a continuous recorder.

(f) Every owner or operator using a boiler or process heater with a design heat input capacity less than one hundred fifty million (150,000,000) Btu per hour that is to comply with section 3 of this rule shall install, calibrate, maintain, and operate, according to the manufacturer's specifications, a temperature monitoring device in the firebox with an accuracy of plus or minus one percent (1%) of the temperature being measured expressed in degrees Celsius or plus or minus one and eight-tenths percent (1.8%) of the temperature being measured expressed in degrees Fahrenheit, equipped with a continuous recorder. Any boiler or process heater in which all process vent streams are introduced with primary fuel is exempt from this requirement.

(g) Every owner or operator of a process vent shall be permitted to monitor by an alternative method or may monitor parameters other than those listed in subsections (a) through (f), if approved by the commissioner and U.S. EPA in writing. The alternative method or parameters shall be contained in a permit pertaining to the process vent as federally enforceable permit conditions.

(Air Pollution Control Board; 326 IAC 8-19-6; filed Nov 3, 2009, 3:32 p.m.: 20091202-IR-326090222FRA)

Authority: IC 13-14-8; IC 13-17-3-4; IC 13-17-3-11

Sec. 7. (a) Every owner or operator of a unit operation or batch process train that is exempt from the control requirements in section 1(c)(2)(A) or 1(c)(2)(B) of this rule shall keep records of the uncontrolled total annual mass emissions for such unit operation or batch process train, as applicable, and documentation verifying these values or measurements. The documentation shall include the engineering calculations, any measurements made in accordance with section 5 of this rule, and the potential or permitted number of batch cycles per year or, in the alternative, total production as represented in the permit pertaining to the unit operation or batch process train.

(b) Every owner or operator of a unit operation or batch process train that is exempt from control requirements of section 1(c)(2) of this rule shall keep the following records:

(1) The uncontrolled total annual mass emissions and documentation verifying these values or measurements. The documentation shall include any engineering calculations, any measurements made in accordance with section 5 of this rule, and the potential or permitted number of batch cycles per year or, in the alternative, total production as represented in the permit pertaining to the unit operation or batch process train.

(2) The average flow rate in scfm and documentation verifying this value.

(3) The calculated weighted average volatility and documentation verifying this value.

(4) The calculated applicability flow rate value from section 1(e)(3) of this rule.

(c) Every owner or operator of a batch process train or unit operation subject to the control requirements of section 3 of this rule shall keep records of the following parameters required to be monitored under section 6 of this rule:

(1) If using a thermal or catalytic incinerator to comply with section 3 of this rule, records indicating the average combustion chamber temperature of the incinerator (or the average temperature upstream and downstream of the catalyst bed for a catalytic incinerator) measured continuously and averaged over the same time period as the compliance test that demonstrated compliance.

(2) If using a flare, either steam-assisted, air-assisted, or nonassisted, to comply with section 3 of this rule, continuous records of the flare pilot flame monitoring and records of all periods of operations during which the pilot flame is absent.

(3) If using any of the following as a control device, the following records:

(A) Where a scrubber is used, the exit specific gravity (or alternative parameter equivalent in ability to measure the degree of absorbing liquid saturation, if approved by the commissioner) and the average exit temperature of the absorbing liquid, measured continuously and averaged over the same time period as the compliance test that demonstrated compliance (both measured while the vent stream is routed normally).

(B) Where a condenser is used, the average exit (product side) temperature measured continuously and averaged over the same time period as the compliance test that demonstrated compliance while the vent stream is routed normally.

(C) Where a carbon adsorber is used, the total steam mass flow measured continuously and averaged over the same time period as the compliance test that demonstrated compliance (full carbon bed cycle), temperature of the carbon bed after regeneration (and within fifteen (15) minutes after completion of any cooling cycle or cycles), and duration of the carbon bed steaming cycle (all measured while the vent stream is routed normally).

(D) As an alternative to clause (A), (B), or (C), at a minimum, records indicating the concentration level or reading indicated by the VOC monitoring device at the outlet of the scrubber, condenser, or carbon adsorber, measured continuously and averaged over the same time period as the compliance test that demonstrated compliance (while the vent stream is routed normally).

(d) Every owner or operator of a unit operation claiming a vent stream concentration exemption level, as set forth in section 1(d)(1) of this rule, shall:

(1) maintain records to indicate the vent stream concentration is less than or equal to five hundred (500) ppmv; and

(2) notify the commissioner in writing if the vent stream concentration at any time equals or exceeds five hundred (500) ppmv, within sixty (60) days after the event.

The notification shall include a copy of all records of the event.

(e) An owner or operator of a batch process train or unit operation subject to the control requirements of section 3 of this rule may maintain alternative records other than those listed in section 1 of this rule. Any alternative record keeping shall be:

(1) approved by the commissioner and U.S. EPA in writing; and

(2) contained in the permit pertaining to the batch process train or unit operation as federally enforceable permit conditions.

(f) The owner or operator of a unit operation or batch process train that is exempt from the control requirements of section 3 of this rule shall notify the commissioner in writing if the uncontrolled total annual mass emissions from such unit operation or batch process train exceed the threshold in section 1(c)(2)(A) or 1(c)(2)(B) of this rule, respectively, within sixty (60) days after the event occurs. The notification shall include a copy of all records of the event.

(g) Every owner or operator of a batch process train or unit operation required to keep records under this rule shall:

(1) maintain the records at the source for a minimum period of five (5) years; and

(2) make the records available to the commissioner upon request.

(Air Pollution Control Board; 326 IAC 8-19-7; filed Nov 3, 2009, 3:32 p.m.: 20091202-IR-326090222FRA)

Authority: IC 13-14-8; IC 13-17-3-4; IC 13-17-3-11

Sec. 8. Reporting requirements are as follows:

(1) Initial compliance status report. Each owner or operator of a batch process train or unit operation subject to this rule shall submit an initial compliance status report within sixty (60) calendar days after the compliance dates specified in section 9 of this rule as follows:

(A) The initial compliance status report shall include the following:

(i) The results of exemption.

(ii) Process vent determinations.

(iii) Compliance tests.

(iv) Values of monitored parameters established during compliance tests.

(v) Any other information used to demonstrate compliance and recorded under section 7 of this rule.

(B) For compliance tests and process vent determinations based on measurements, the initial compliance status report shall include one (1) complete test report for each test method used for a particular kind of process vent. For additional tests and measurements performed for the same kind of process vent using the same test method, the test results or measurement results shall be submitted, but a complete test report is not required.

(C) A complete test report shall include the following:

(i) A brief process description.

(ii) A sampling site description.

(iii) A description of sampling and analysis procedures and any modifications to standard procedures.

(iv) Quality assurance procedures.

(v) A record of operating conditions during the test.

(vi) A record of preparation of standards.

(vii) A record of calibrations.

(viii) Raw data sheets for field sampling.

(ix) Raw data sheets for field and laboratory analyses.

(x) Documentation of calculations.

(xi) Any other information required by the test method.

(D) For each monitored parameter for which a range is required to be established under section 5(i) of this rule, the compliance status report shall include the following information:

(i) The specific range of the monitored parameter or parameters for each control device.

(ii) The rationale for the specific range for each parameter for each control device, including the following:

(AA) Any data and calculations used to develop the range.

(BB) A description of why the range indicates proper operation of the control device or final recovery device.

(2) Semiannual compliance status reports. The owner or operator of a batch process train or unit operation subject to this rule shall submit semiannual compliance status reports containing the information in clauses (A) and (B). The semiannual compliance status report shall be submitted no later than sixty (60) calendar days after the end of each six (6) month period to the department. The first report shall be submitted no later than eight (8) months after the date the initial compliance status report is due and shall cover the six (6) month period beginning on the date the initial compliance status report is due as follows:

(A) Semiannual reports on parameter monitoring for controlled process vents. For a process vent equipped with a control device to meet the requirement of section 3 of this rule, the semiannual compliance status reports shall include the following recorded information:

(i) Reports of monitored parameters for all operating days when the average values recorded under section 7(c) of this rule were outside the ranges established in the initial compliance status report or permit issued by the commissioner.

(ii) Reports of the times and durations of all periods recorded under section 9(3) of this rule when the monitoring device is not working or monitoring data is not collected during process operation generating the process vent stream or during operation of the control or recovery device.

(iii) Reports of the times and durations of all periods recorded under section 7(c)(2) of this rule in which the pilot flame is absent.

(iv) Reports on monitoring devices and parameters approved by the commissioner under section 7(e) of this rule.

(B) Semiannual reports on subsequent compliance tests for controlled process vents and subsequent process vent determination tests. If any subsequent compliance tests or subsequent process vent determination tests are conducted during the semiannual reporting period after the initial compliance status report has been submitted, the semiannual compliance status report shall include the data recorded under section 7 of this rule.

(Air Pollution Control Board; 326 IAC 8-19-8; filed Nov 3, 2009, 3:32 p.m.: 20091202-IR-326090222FRA)

Authority: IC 13-14-8; IC 13-17-3-4; IC 13-17-3-11

Sec. 9. Except where otherwise specified in this rule, the compliance dates for any batch process train that is subject to this rule are as follows:

(1) If installation commenced before the effective date of this rule, the compliance date of the batch process train is:

(A) April 1, 2011; or

(B) the date the source becomes subject to this rule;

whichever is later.

(2) If installation commenced on or after the effective date on this rule, the compliance date of the batch process train is the date of initial startup of the batch process train.

(3) If a source reduces its potential to emit under section 1(b) of this rule, the date on which the source subsequently meets the applicability criteria of section 1(a) of this rule is the date the source becomes subject to this rule.

(4) If a batch process train or unit operation is exempted under section 1(c)(2) of this rule or is not required to reduce uncontrolled VOC emissions under section 3(1) or 3(2) of this rule and is subsequently equipped with a control device to meet the VOC reduction requirements of section 3(1) or 3(2) of this rule, the compliance date of the batch process train or unit operation is the date of first startup of the installed control device. Until the date of first startup of the installed control device, the batch process train or unit operation shall continue to meet either the exemption level or the criteria pertaining to applicability equations.

(5) For any control device that is used to comply with section 3 of this rule, the owner or operator shall demonstrate compliance by testing the control device in accordance with section 5 of this rule within ninety (90) days after the compliance date.

(6) Additional testing of the control device or testing of the process vents of a batch process train or unit operation in accordance with section 5 of this rule may be required by the commissioner to ensure continued compliance with section 3 of this rule.

(Air Pollution Control Board; 326 IAC 8-19-9; filed Nov 3, 2009, 3:32 p.m.: 20091202-IR-326090222FRA)

Rule 20. Industrial Wastewater

Authority: IC 13-14-8; IC 13-17-3-4; IC 13-17-3-11

Sec. 1. (a) This rule applies to any source that generates process wastewater and meets all of the following criteria:

(1) Is located in Lake County or Porter County.

(2) Has the combined total potential to emit VOC emissions equal to or greater than one hundred (100) tons per year from all of the following:

(A) Industrial wastewater sources (all waste management units).

(B) All noncontrol technique guideline (non-CTG) sources.

(C) Unregulated emissions from CTG emission units, except emission units regulated under 40 CFR 60, Subpart BBB*; 40 CFR 60, Subpart III*; 40 CFR 60, Subpart NNN*; or 40 CFR 63, Subpart T*.

(3) Has facility operations specifically listed under any of the following industrial categories:

(A) Organic chemicals, plastics, and synthetic fibers manufacturing industry under Standard Industrial Classification (SIC) codes 2821, 2823, 2824, 2865, and 2869.

(B) Pharmaceutical industry under SIC codes 2833, 2834, and 2836.

(C) Pesticide manufacturing industry under SIC code 2879.

(D) Hazardous waste treatment, storage, and disposal facilities under SIC codes 4952, 4953, and 4959.

(b) If a source meets the applicability requirements under subsection (a), but reduces its potential to emit for VOCs by means of federally enforceable operational restrictions (for example, production, hours of operation, or capacity utilization) to less than one hundred (100) tons per year by April 1, 2011, the source is not subject to the emission control requirements of section 3 of this rule.

(c) For purposes of subsection (a), an emission unit shall be considered regulated by a rule, section, or subpart if it is subject to the limits of that rule, section, or subpart. An emission unit is not considered regulated by a rule, section, or subpart if it is not subject to the limits of that rule, section, or subpart. For example, if the emission unit is covered by an exemption in the rule, section, or subpart, or the applicability criteria of the rule, section, or subpart are not met, then the source is not subject to the rule, section, or subpart. An emission unit is also not considered regulated if there is no rule contained in this article regulating the source category.

(Air Pollution Control Board; 326 IAC 8-20-1; filed Nov 3, 2009, 3:32 p.m.: 20091202-IR-326090222FRA)

Authority: IC 13-14-8; IC 13-17-3-4; IC 13-17-3-11

Sec. 2. The following definitions apply throughout this rule:

(1) "Affected residual" means a residual that is removed from an affected VOC wastewater stream.

(2) "Affected VOC" means VOC with a Henry's Law Constant greater than or equal to 1.8 × 10-6 atm-m3/mole (0.1y/x) at twenty-five (25) degrees Celsius.

(3) "Affected VOC wastewater stream" means the following:

(A) A process wastewater stream from a process unit at an affected industrial category with either an annual average concentration of affected VOC greater than or equal to:

(i) ten thousand (10,000) parts per million by weight (ppmw); or

(ii) one thousand (1,000) ppmw and an annual average flow rate greater than or equal to ten and zero-tenths (10.0) liters per minute (two and sixty-four hundredths (2.64) gallons per minute), as determined in accordance with section 9 of this rule.

(B) The term does not include the following:

(i) Maintenance wastewaters.

(ii) Stormwater from segregated sewers.

(iii) Water from firefighting and deluge systems.

(iv) Spills.

(v) Water from safety showers.

(vi) Samples of a size not greater than reasonably necessary for the method of analysis that is used.

(vii) Equipment leaks.

(viii) Wastewater drips from procedures such as disconnecting hoses after cleaning lines.

(ix) Noncontact cooling water.

(4) "Annual average concentration" means the flow-weighted annual average concentration, as determined according to the procedures specified in 40 CFR 60.782(b)*.

(5) "Annual average flow rate" means the annual average flow rate, as determined according to the procedures specified in section 9 of this rule.

(6) "Closed biological treatment process" means a tank or surface impoundment where biological treatment occurs and VOC emissions from the treatment process are routed either to a control device by means of a closed vent system or to a fuel gas system by means of hard-piping. The tank or surface impoundment has a fixed roof, as defined in this rule, or a floating flexible membrane cover that meets the requirements specified in section 9 of this rule.

(7) "Closed-vent system" means a system that:

(A) is not open to the atmosphere; and

(B) is composed of:

(i) hard-piping;

(ii) ductwork;

(iii) connections; and

(iv) if necessary, flow inducing devices that transport gas or vapor from an emission point to a control device.

(8) "Combustion device" means an individual unit of equipment, such as a:

(A) flare;

(B) incinerator;

(C) process heater; or

(D) boiler;

used for the combustion of VOC emissions.

(9) "Continuously monitor and record" means to measure data values of a parameter at least once every fifteen (15) minutes and to record either each measured data value or block average values for a fifteen (15) minute or shorter time period. A block average value is the average of all measured data values during the time period or, if data values are measured more frequently than once per minute, the average of measured data values taken at least once per minute during the time period.

(10) "Continuous seal" means a seal that forms a continuous closure that completely covers the space between the wall of the storage vessel and the edge of the floating roof. A continuous seal may be a:

(A) vapor-mounted seal;

(B) liquid-mounted seal; or

(C) metallic shoe seal.

A continuous seal may be constructed of fastened segments so as to form a continuous seal.

(11) "Control device" means any of the following:

(A) Combustion device.

(B) Recovery device for vapor vents.

(C) Recapture device.

Such equipment includes, but is not limited to, absorbers, carbon adsorbers, condensers, incinerators, flares, boilers, and process heaters. For a steam stripper, a primary condenser is not considered a control device.

(12) "Cover" means the following:

(A) A device or system that is placed on or over a waste management unit containing wastewater or residuals so that the entire surface area is enclosed to minimize air VOC emissions.

(B) A cover may have openings necessary for operation, inspection, and maintenance of the waste management unit, such as:

(i) access hatches;

(ii) sampling ports; and

(iii) gauge wells;

provided that each opening is closed when not in use.

(C) The following are examples of covers:

(i) A fixed roof installed on a wastewater tank.

(ii) A lid installed on a container.

(iii) An air-supported enclosure installed over a waste management unit.

(13) "Ductwork" means a conveyance system such as those commonly used for heating and ventilation systems. It often:

(A) is made of sheet metal; and

(B) has sections connected by screws or crimping.

Hard-piping is not ductwork.

(14) "Enhanced biological treatment process" means the following:

(A) An aerated, thoroughly mixed treatment unit or units that contains biomass suspended in water followed by a clarifier that removes biomass from the treated water and recycles recovered biomass to the aeration unit.

(B) The mixed liquor volatile suspended solids (biomass) is greater than one (1) kilogram per cubic meter throughout each aeration unit. The biomass is suspended and aerated in the water of the aeration unit or units by either submerged air flow or mechanical agitation.

(C) A thoroughly mixed treatment unit is a unit that is designed and operated to approach or achieve uniform biomass distribution and organic compound concentration throughout the aeration unit by quickly dispersing the recycled biomass and the wastewater entering the unit.

(15) "External floating roof" means a pontoon-type or double-deck-type cover that rests on the liquid surface in a storage vessel or waste management unit with no fixed roof.

(16) "Fixed roof" means a cover that:

(A) is mounted on a waste management unit or storage vessel in a stationary manner; and

(B) does not move with fluctuations in liquid level.

(17) "Floating roof" means a cover:

(A) consisting of a:

(i) double deck;

(ii) pontoon single deck;

(iii) internal floating cover; or

(iv) covered floating roof;

that rests upon and is supported by the liquid being contained; and

(B) that is equipped with a closure seal or seals to close the space between the roof edge and waste management unit.

(18) "Fr" means fraction removed value for VOC, unitless.

(19) "Fuel gas system" means the off-site and on-site piping and control system that gathers gaseous stream or streams generated by on-site operations, may blend them with other sources of gas, and transports the gaseous stream for use as fuel gas in combustion devices or in in-process combustion equipment, such as furnaces and gas turbines, either singly or in combination.

(20) "Hard-piping" means pipe or tubing.

(21) "Incinerator" means an enclosed combustion device that is used for destroying organic compounds. Auxiliary fuel may be used to heat waste gas to combustion temperatures. Any energy recovery section present is not physically formed into one (1) manufactured or assembled unit with the combustion section; rather, the energy recovery section is a separate section following the combustion section and the two are joined by ducts or connections carrying flue gas. The energy recovery section limitation does not apply to an energy recovery section used solely to preheat the incoming vent stream or combustion air.

(22) "Individual drain system" means the stationary system used to convey wastewater streams or residuals to a waste management unit or to discharge or disposal. The term includes:

(A) hard-piping;

(B) all process drains and junction boxes, together with their associated sewer lines and other junction boxes;

(C) manholes;

(D) sumps and lift stations;

(E) conveying wastewater streams; or

(F) residuals.

The term does not include a segregated storm water sewer system, which is a drain and collection system designed and operated for the sole purpose of collecting rainfall-runoff at a source, and which is segregated from all other individual drain systems.

(23) "Internal floating roof" means a cover that rests or floats on the liquid surface, but not necessarily in complete contact with it, inside a waste management unit that has a fixed roof.

(24) "Junction box" means a manhole or a lift station or access point to a wastewater sewer line.

(25) "Liquid-mounted seal" means a foam or liquid-filled seal mounted in contact with the liquid between the wall of the storage vessel or waste management unit and the floating roof. The seal is mounted continuously around the circumference of the vessel or unit.

(26) "Maintenance wastewater" means wastewater generated by the draining of process fluid from components in the process unit into an individual drain system prior to or during maintenance activities. Maintenance wastewater can be generated during planned and unplanned shutdowns and during periods not associated with a shutdown. Any generation of wastewater that is routine or is generated by designed manufacturing processes is not maintenance wastewater. Examples of activities that can generate maintenance wastewaters include the following:

(A) Descaling heat exchanger tubing bundles.

(B) Cleaning of distillation column traps.

(C) Draining of low legs and high point bleeds.

(D) Draining of pumps into an individual drain system.

(E) Draining of portions of the process unit for repair.

(27) "Mechanical shoe seal" or "metallic shoe seal" means metal sheets that are held vertically against the wall of the storage vessel by:

(A) springs;

(B) weighted levers; or

(C) other mechanisms;

and connected to the floating roof by braces or other means. A flexible coated fabric (envelope) spans the annular space between the metal sheet and the floating roof.

(28) "Oil-water separator" or "organic-water separator" means the following:

(A) A waste management unit used to separate oil or organics from water.

(B) An oil-water or organic-water separator consists of not only the separation unit but also the forebay and other separator basins:

(i) skimmers;

(ii) weirs;

(iii) grit chambers; and

(iv) sludge hoppers;

and bar screens that are located directly after the individual drain system and prior to additional treatment units such as an air flotation unit clarifier, or biological treatment unit.

(C) Examples of an oil-water or organic-water separator include, but are not limited to:

(i) an American Petroleum Institute separator;

(ii) a parallel-plate interceptor; or

(iii) a corrugated-plate interceptor with the associated ancillary equipment.

(29) "Open biological treatment process" means a biological treatment process that is not a closed biological treatment process as defined in this rule.

(30) "Point of determination" means each point where process wastewater exits a process unit.

(31) "Point of generation" means the location where process wastewater exits a process unit.

(32) "Pressure relief valve" means a valve used only to release an unplanned, nonroutine discharge. A relief valve discharge can result from:

(A) an operator error;

(B) a malfunction, such as a power failure or equipment failure; or

(C) another unexpected cause;

that requires immediate venting of gas from process equipment in order to avoid safety hazards or equipment damage.

(33) "Process drain" means any opening (including a covered or controlled opening) that is installed or used to receive or convey wastewater into the wastewater system.

(34) "Process unit" means the smallest set of process equipment that:

(A) can operate independently; and

(B) includes all operations necessary to achieve its process objective.

(35) "Process wastewater" means the following:

(A) Wastewater that during manufacturing or processing comes into direct contact with or results from the production or use of any:

(i) raw material;

(ii) intermediate product;

(iii) finished product;

(iv) byproduct; or

(v) waste product.

(B) The term includes, but is not limited to, the following:

(i) Product tank drawdown or feed tank drawdown.

(ii) Water formed during a chemical reaction or used as a reactant.

(iii) Water used to wash impurities from organic products or reactants.

(iv) Water used to cool or quench organic vapor streams through direct contact.

(v) Condensed steam from jet ejector systems pulling vacuum on vessels containing organics.

(36) "RCRA" means the Resource Conservation and Recovery Act.

(37) "Recapture device" means the following:

(A) An individual unit of equipment capable of and used for the purpose of recovering chemicals, but not normally for use, reuse, or sale. For example, a recapture device may recover chemicals primarily for disposal.

(B) Recapture devices include, but are not limited to, the following:

(i) Absorbers.

(ii) Carbon adsorbers.

(iii) Condensers.

(38) "Recovery device" means the following:

(A) An individual unit of equipment capable of and normally used for the purpose of recovering chemicals for fuel value (for example, net positive heating value), use, reuse, or for sale for fuel value, use, or reuse.

(B) Examples of equipment that may be recovery devices include the following:

(i) Absorbers.

(ii) Carbon adsorbers.

(iii) Condensers.

(iv) Oil-water separators or organic-water separators.

(v) Organic removal devices, such as the following:

(AA) Decanters.

(BB) Strippers.

(CC) Thin-film evaporation units.

(C) For purposes of the monitoring, record keeping, and reporting requirements of this rule, recapture devices are considered recovery devices.

(39) "Residual" means the following:

(A) Any liquid or solid material containing VOC that is removed from a wastewater stream by a waste management unit or treatment process that does not destroy organic compounds (nondestructive unit).

(B) Examples of residuals from nondestructive wastewater management units are the following:

(i) The organic layer and bottom residue removed by a decanter or organic-water separator.

(ii) The overheads from a steam stripper or air stripper.

(C) Examples of materials that are not residuals are:

(i) silt;

(ii) mud;

(iii) leaves;

(iv) bottoms from a steam stripper or air stripper; and

(v) sludges, ash, or other materials;

removed from wastewater being treated by destructive devices such as biological treatment units and incinerators.

(40) "Sewer line" means a lateral, trunk line, branch line, or other conduit including, but not limited to, grates and trenches, used to convey wastewater streams or residuals to a downstream waste management unit.

(41) "Single-seal system" means a floating roof having one (1) continuous seal that completely covers the space between the wall of the storage vessel and the edge of the floating roof. The seal may be a vapor-mounted, liquid-mounted, or metallic shoe seal.

(42) "Steam jet ejector" means a steam nozzle that discharges a high-velocity jet across a suction chamber that is connected to the equipment to be evacuated.

(43) "Steam stripper" means a column including:

(A) associated stripper feed tanks;

(B) condensers; or

(C) heat exchangers;

used to remove compounds from wastewater.

(44) "Surface impoundment" means the following:

(A) A waste management unit that is a:

(i) natural topographic depression;

(ii) man-made excavation; or

(iii) diked area formed primarily of earthen materials (although it may be lined with man-made materials);

designed to hold an accumulation of liquid wastes or waste containing free liquids.

(B) A surface impoundment is used for the purpose of treating, storing, or disposing of wastewater or residuals and is not an injection well.

(C) Examples of surface impoundments are the following:

(i) Equalization.

(ii) Settling and aeration pits.

(iii) Ponds.

(iv) Lagoons.

(45) "Tank drawdown" means any material or mixture of materials discharged from a product tank, feed tank, or intermediate tank for the purpose of removing water or other contaminants from the tank.

(46) "Temperature monitoring device" means a unit of equipment used to monitor temperature and having a minimum accuracy of:

(A) plus or minus one percent (1%) of the temperature being monitored expressed in degrees Celsius; or

(B) plus or minus five-tenths (0.5) degree Celsius;

whichever number is greater, for example, has the highest absolute value.

(47) "Treatment process" means a specific technique that removes or destroys the organics in a wastewater or residual stream, such as:

(A) a steam stripping unit (steam stripper);

(B) a thin-film evaporation unit;

(C) a waste incinerator;

(D) a biological treatment unit; or

(E) any other process applied to wastewater streams or residuals;

to comply with section 4(h) or 5 of this rule. Most treatment processes are conducted in tanks. Treatment processes are a subset of waste management units.

(48) "Vapor-mounted seal" means a continuous seal that:

(A) completely covers the annular space between the wall of the storage vessel or waste management unit and the edge of the floating roof; and

(B) is mounted such that there is a vapor space between the stored liquid and the bottom of the seal.

(49) "Waste management unit" means the following:

(A) Equipment, a structure or structures, or a device or devices used to convey, store, treat, or dispose of wastewater streams or residuals.

(B) Examples of waste management units include the following:

(i) Wastewater tanks.

(ii) Surface impoundments.

(iii) Individual drain systems.

(iv) Biological wastewater treatment units.

(C) Examples of equipment that may be waste management units include the following:

(i) Containers.

(ii) Air flotation units.

(iii) Oil-water separators or organic-waste separators.

(iv) Organic removal devices such as:

(AA) decanters;

(BB) strippers; or

(CC) thin-film evaporation units.

(D) If such equipment is used for recovery, then it is part of a process unit and is not a waste management unit.

(50) "Wastewater stream" means a stream that contains process wastewater.

(51) "Wastewater tank" means a stationary waste management unit that is:

(A) designed to contain an accumulation of wastewater or residuals; and

(B) constructed primarily of nonearthen materials, for example, wood, concrete, steel, or plastic, that provide structural support.

The term includes wastewater tanks used for flow equalization.

(52) "Water seal controls" means:

(A) a seal pot;

(B) a p-leg trap; or

(C) another type of trap filled with water;

for example, flooded sewers that maintain water levels adequate to prevent air flow through the system, that creates a water barrier between the water level of the seal and the atmosphere. The water level of the seal must be maintained in the vertical leg of a drain in order to be considered a water seal.

(53) "Wet weather retention basin" means an impoundment or tank that is used to store rainfall runoff that would exceed the capacity of the wastewater treatment system until it can be returned to the wastewater treatment system or, if the water meets the applicable discharge limits, discharged without treatment. These units may also be used to store wastewater during periods when the wastewater treatment system is shut down for maintenance or emergencies.

*These documents are incorporated by reference. Copies may be obtained from the Government Printing Office, 732 North Capitol Street NW, Washington, D.C. 20401 or are available for review and copying at the Indiana Department of Environmental Management, Office of Legal Counsel, Indiana Government Center North, Thirteenth Floor, 100 North Senate Avenue, Indianapolis, Indiana 46204.

(Air Pollution Control Board; 326 IAC 8-20-2; filed Nov 3, 2009, 3:32 p.m.: 20091202-IR-326090222FRA)

326 IAC 8-20-3 Overall requirements for industrial wastewater

Authority: IC 13-14-8; IC 13-17-3-4; IC 13-17-3-11

Sec. 3. The owner or operator of a source subject to this rule shall ensure that all of the following are met:

(1) Except as otherwise exempted under subdivision (2), the owner or operator of a source that meets the applicability criteria in section 1 of this rule shall comply with the requirements in sections 4 through 12 of this rule.

(2) The following exemptions apply:

(A) Any source with an annual affected VOC loading in wastewater, as determined in accordance with section 9 of this rule, less than or equal to ten (10) megagrams (eleven and three-hundredths (11.03) tons) is exempt from the control requirements of section 4 of this rule.

(B) At any source with an annual affected VOC loading in wastewater, as determined in accordance with section 9 of this rule, greater than ten (10) megagrams (eleven and three-hundredths (11.03) tons), the owner or operator of the source may exempt from the control requirements of section 4 of this rule one (1) or more affected VOC wastewater streams for which the sum of the annual VOC loading in wastewater for all of the exempted streams is less than or equal to ten (10) megagrams (eleven and three-hundredths (11.03) tons).

(C) If compliance with the control requirements of section 4 of this rule would create a safety hazard in a waste management unit, the owner or operator may request U.S. EPA to exempt that waste management unit from the control requirements of section 4 of this rule. U.S. EPA shall approve the request if justified by the likelihood and magnitude of the potential injury and if U.S. EPA determines that reducing or eliminating the hazard is technologically or economically unreasonable. The approval shall occur when the department is informed, in writing, that U.S. EPA has no objections to this exemption.

(D) Wet weather retention basins are exempt from the requirements of this rule.

(Air Pollution Control Board; 326 IAC 8-20-3; filed Nov 3, 2009, 3:32 p.m.: 20091202-IR-326090222FRA)

326 IAC 8-20-4 Control requirements for process wastewater

Authority: IC 13-14-8; IC 13-17-3-4; IC 13-17-3-11

Sec. 4. (a) Any waste management unit that receives, manages, or treats an affected VOC wastewater stream or affected residual shall be controlled in accordance with:

(1) this section; or

(2) one (1) of the alternate methods of control listed in section 5 of this rule.

(b) The control requirements apply from the point of generation of an affected VOC wastewater stream until the affected VOC wastewater stream, including any affected residual, is either returned to a process unit or treated in accordance with subsection (h).

(c) For each individual drain system that receives or manages an affected VOC wastewater stream or an affected residual, the owner or operator shall comply with the following requirements:

(1) The owner or operator shall operate and maintain on each opening in the individual drain system a cover and, if vented, route the vapors to a process or through a closed vent system to a control device as follows: